Quality Guard

How it works

Q.G EDGE CLIENT

Q.G EDGE CLIENT

data collection

real-time monitoring

control

1

Data collection

Monitoring and control are available at the same time.

You can collect and monitor huge amounts of information

on the processing machine with just one Ethernet(LAN) to the CNC,

the remote control such as an alarm or emergency

stop may be performed if any abnormality has been detected.

You can collect and monitor huge amounts of information

on the processing machine with just one Ethernet(LAN) to the CNC,

the remote control such as an alarm or emergency

stop may be performed if any abnormality has been detected.

Loading dose,

temperature, rpm

Temperature

(encoder),

Loading dose, an insulation state

FAN,

condenser state

Performance of D-Light Partner_ date collection

with ms level response rate.

Fast collection speed is essential

for real-time monitoring and tip wear/fine break detection.

Quality Guard provides data collection

at a response rate of 0.001 seconds.

for real-time monitoring and tip wear/fine break detection.

Quality Guard provides data collection

at a response rate of 0.001 seconds.

2

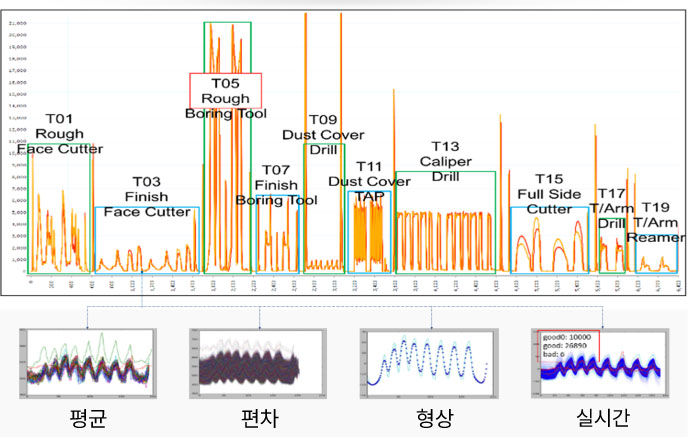

Real-time monitoring

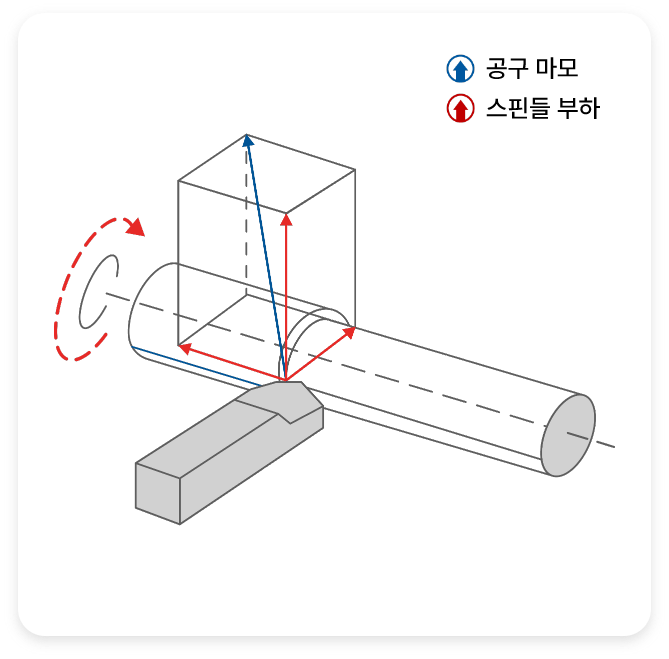

· 공구가 마모될수록 스핀들 부하는 상승

· 정상 가공 스핀들 부하의 경향으로 이상 감지

· 정상 가공 스핀들 부하의 경향으로 이상 감지

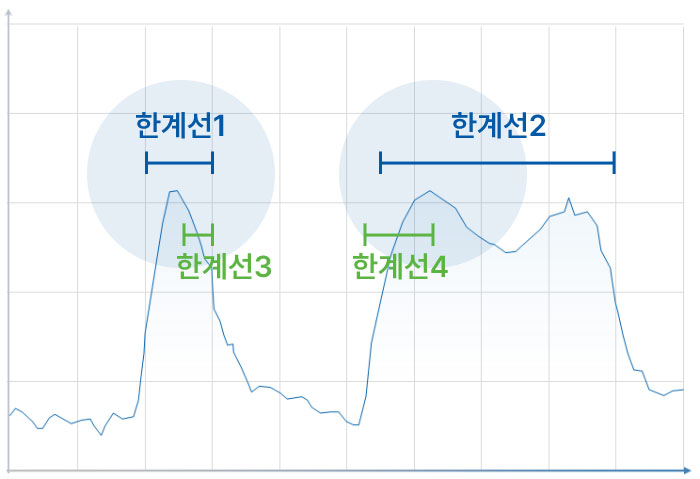

Performance of D-Light Partner_ Inspection

simulation using a long period

Quality Guard adopted a simulation inspection method using long-term data to increase

the possibility of detection and reduce the possibility of misjudgment,

exceeding the limitations of existing monitoring methods.

Quality Guard adopted a

simulation inspection method

using long-term data to increase

the possibility of detection and reduce

the possibility of misjudgment,

exceeding the limitations of

existing monitoring methods.

simulation inspection method

using long-term data to increase

the possibility of detection and reduce

the possibility of misjudgment,

exceeding the limitations of

existing monitoring methods.

Traditional tool

monitoring methods

Q.G Tool Monitoring

Methods

Application of industrial mathematical examination techniques.

3

Facility control

Performance of D-Light Partner_ field knowledge

Control the facility in the way the field wants with a high-level acknowledgment of machines

(Feed Hold, Optional Stop, Cycle Stop, Etc.)

Control the facility in the way

the field wants with a high-level

acknowledgment of machines

(Feed Hold, Optional Stop, Cycle Stop, Etc.)

the field wants with a high-level

acknowledgment of machines

(Feed Hold, Optional Stop, Cycle Stop, Etc.)

Also makes maintenance easier with the remote control.

Also makes maintenance easier

with the remote control.

with the remote control.